Transformers are essential to energy infrastructure, serving as indispensable equipment for the transmission and distribution of electricity. Their primary function is to increase or decrease voltage levels while keeping the transmitted power virtually constant. On one hand, they enable the transport of large amounts of energy while drastically reducing losses during transmission; on the other, they step down high voltage to safe levels so that electricity can be used securely in homes, factories, and commercial buildings.

To ensure the efficiency and service life of transformers, they are equipped with cooling systems that regulate the temperature of insulating materials, keeping them within the limits established by their respective thermal classes, as defined by national and international standards. Proper cooling dissipates the heat generated during operation, preventing the degradation of insulating materials and minimizing the risk of short circuits due to overheating, which, in extreme cases, can lead to severe fires.

Transformer cooling systems are specified on the equipment's nameplates. In this article, we will cover two of the most common types: ONAN and ONAF.

The acronym ONAN stands for Oil Natural, Air Natural.

In an ONAN system, transformer cooling occurs naturally, with the oil circulating via natural convection without the use of pumps, transferring the heat generated by the windings to the radiator elements. This heat is then dissipated into the environment by the surrounding air, also through natural convection. This cooling method is typically applied to lower-capacity transformers, making it a more cost-effective and low-maintenance solution, ideal for installations with moderate load variations.

The acronym ONAF stands for Oil Natural, Air Forced.

In an ONAF system, the oil continues to circulate via natural convection inside the transformer; however, fans are installed externally to force air to circulate between the radiator elements (whether panels or tubes). This forced ventilation significantly improves heat dissipation compared to the ONAN system, allowing the transformer to operate at a higher capacity.

ONAF is widely used in medium and high-power transformers, as the increased cooling capacity allows for more efficient operation under heavy loads. This system ramps up the necessary heat dissipation based on energy demand, ensuring greater flexibility and operational stability in the face of load fluctuations.

Understanding ONAN and ONAF cooling systems is essential to ensuring efficient transformer operation, as each system offers specific characteristics tailored to different power and cooling requirements. The correct application of each method guarantees effective heat dissipation, ensuring equipment safety and durability. By investing in the appropriate cooling systems, companies can optimize transformer performance, extend service life, and ensure a stable and reliable power supply for their operations.

With decades of experience in the energy sector, Marangoni-Meiser is a leading manufacturer of Radiators, Cooling Fans, and Valves.

We offer customized solutions tailored to each client’s specific needs and projects, developing bespoke radiators for transformers that align with the most rigorous quality standards.

Our products comply with international standards, ensuring thermal efficiency and reliable performance for transformer cooling systems. Our team of specialists provides expert solutions and technical support, backed by extensive experience in the global market.

Request a quote today and discover how we can meet your needs with excellence!

The result of a successful partnership, Marangoni and Meiser—companies that already operate a joint venture in Brazil...

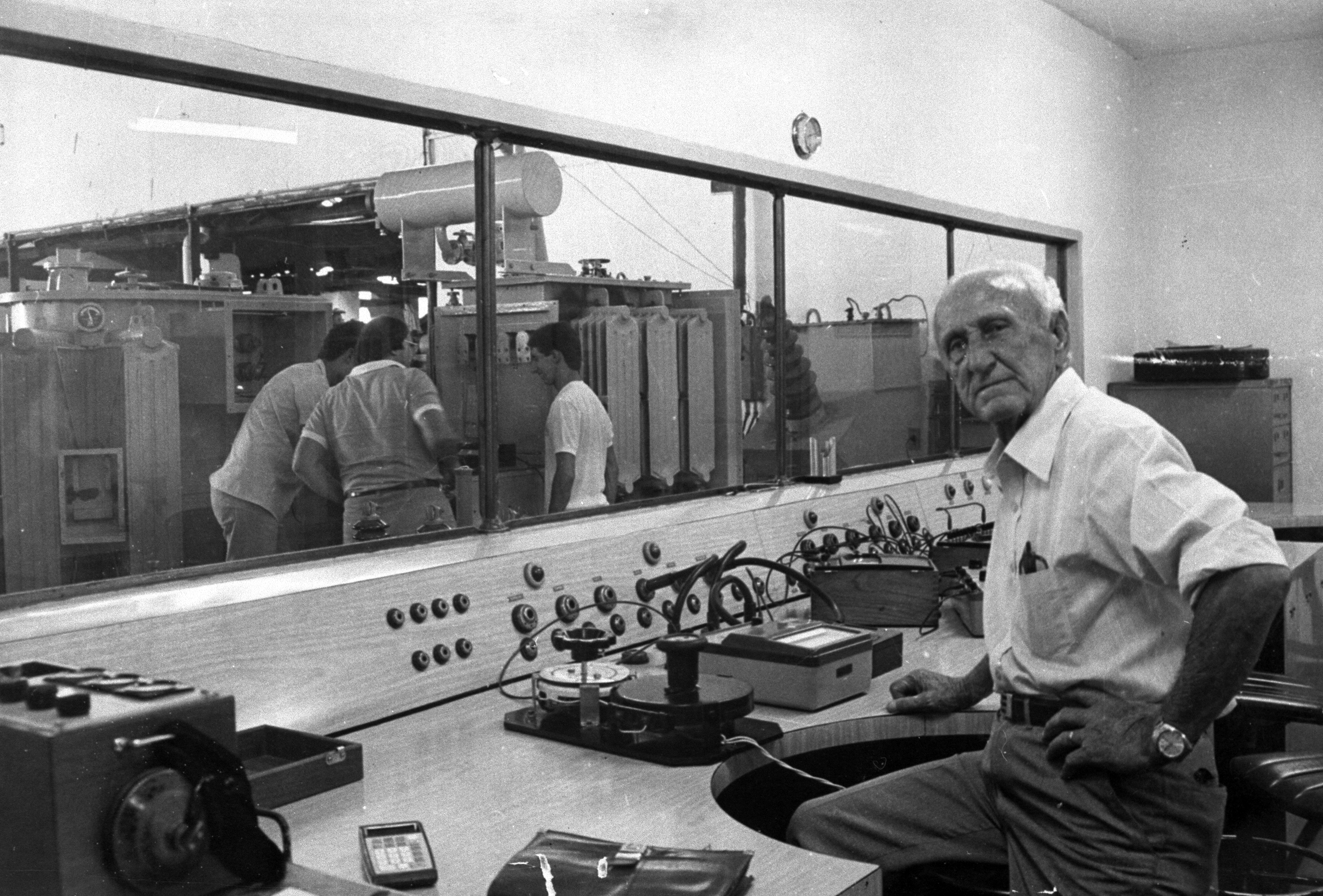

In the early 1940s, Mr. José Marangoni founded a small electrical equipment repair shop in the city of Mogi Mirim...

Developed by

Reami Co. -

Marangoni•Meiser © All

rights reserved.